Selecting the right PVDF pipe for your project can be daunting. Polyvinylidene fluoride (PVDF) pipes have gained popularity in various industries. They are known for their chemical resistance and durability, making them a top choice. According to industry reports, the global demand for PVDF pipes is projected to grow significantly, reaching USD 1.5 billion by 2026.

When choosing a PVDF pipe, consider the specific application requirements. Temperature tolerance, pressure ratings, and chemical compatibility are crucial factors. Not all PVDF pipes meet the same standards. Some may not perform well under extreme conditions, leading to potential failures in your project. This poses a risk to both safety and budget.

Additionally, the manufacturing quality of PVDF pipes varies. Working with reputable suppliers can significantly influence project outcomes. Investing time in research may prevent costly mistakes. Many professionals overlook critical specifications when sourcing materials. Ensuring that you have the correct information can save you from future headaches. Always question the capabilities of the PVDF pipe you plan to use.

PVDF pipes are made from polyvinylidene fluoride. This material has unique properties that make it stand out in various applications. One of its significant advantages is its chemical resistance. It can handle a wide range of corrosive substances without deteriorating. This makes it an excellent choice for industries such as chemical processing and pharmaceuticals. The durability of PVDF pipes ensures long-term performance.

Another critical feature of PVDF is its temperature resistance. These pipes can function well under both high and low temperatures. They maintain integrity even in extreme conditions. However, one must consider the specific temperature range for their project to avoid issues. It’s easy to overlook the environment in which the pipes will be used.

Despite its many benefits, choosing PVDF pipes requires careful thought. Not every project will need the strength or resistance these pipes offer. Sometimes, less expensive materials might be sufficient. Evaluating project requirements thoroughly is essential. A hasty decision could lead to unnecessary costs or performance issues down the line. It’s vital to weigh the pros and cons of different pipe materials deeply and not to rush the selection process.

PVDF pipes are widely used across various industries due to their excellent chemical resistance and durability. These properties make them ideal for applications in chemical processing, water treatment, and pharmaceuticals. A report by the Global Plastics Association notes that the demand for PVDF pipes is projected to grow by 6% annually, driven by these industries.

In the chemical industry, PVDF pipes handle aggressive fluids. They resist corrosion from acids and solvents, allowing for safer operations. In water treatment plants, their robustness ensures a long lifespan. However, choosing the right pipe size and fittings can be challenging. Oversized pipes can lead to inefficiencies. It’s crucial to assess your specific needs carefully.

Tips: Always consider the fluid type and operating temperature. A mismatch might lead to leaks or failures. Engage experts when unsure about material compatibility. Consider doing a pilot test under real conditions. This helps identify potential setbacks before full-scale implementation. Such preparations can save time and resources later.

Choosing the right PVDF pipe for your project involves several critical factors. One must consider the chemical resistance required for specific applications. For instance, studies indicate that PVDF can resist corrosive agents like sulfuric acid, making it a top choice for chemical processing. However, not all formulations of PVDF provide the same level of resistance.

Another essential factor is temperature tolerance. PVDF pipes can handle temperatures up to 140°C. Yet, this capacity varies based on the specific use. Misestimation can lead to failure in high-temperature environments. It's vital to refer to technical data sheets, but they can be challenging to interpret. Ensuring the right thermal conductivity and expansion characteristics is crucial.

Finally, mind the installation complexity. Many users underestimate the challenges involved in joining PVDF pipes. Proper fusion techniques or sealing methods must be applied. A slight miscalculation here can lead to leaks or structural failures. Engaging with professionals can mitigate some risks. At the same time, costs and time demands can be high, creating potential stress for project managers.

This chart illustrates key factors to consider when selecting PVDF pipes, including chemical resistance, temperature tolerance, and pressure rating. Understanding these factors is crucial for ensuring the right choice for your project.

When choosing PVDF pipes, sizing and dimension guidelines are crucial. In many industries, such as chemical processing and pharmaceuticals, accurate sizing affects efficiency. PVDF pipes come in various diameters and lengths. A recent industry report indicates that optimizing pipe sizes can improve flow rates by up to 15%.

Understanding the specific requirements of your project is vital. The internal diameter must align with the system's flow requirements. Heightened temperatures and pressures may demand thicker walls. Many engineers overlook friction losses; these can significantly impact performance. Industry standards suggest that even minor deviations in diameter can lead to a 10% drop in flow rate.

However, common mistakes persist. Some projects fail to properly calculate thermal expansion. Ignoring this can cause leaks or system failures. Additionally, selecting the wrong size can lead to inefficiencies. All components should be carefully considered, including fittings and valves. Dimensions should promote smooth transitions to avoid turbulence. Every detail matters in maintaining system integrity and efficiency.

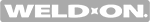

When choosing PVDF pipes for your project, it’s crucial to think about maintenance and lifespan. PVDF pipes are known for their durability. However, they are not indestructible. Regular inspection is essential. Look for any signs of wear or damage. Even minor cracks can lead to bigger problems down the line.

Maintenance plays a key role in extending the life of PVDF systems. Clean the pipes periodically. Debris can accumulate, affecting performance. Use appropriate cleaning solutions that are compatible with PVDF. Be cautious with chemical exposure. Not all substances are safe for PVDF. Over time, constant exposure can weaken the pipes.

Understanding the environment where the pipes will be installed is important. Factors like temperature and pressure can affect lifespan. In extreme conditions, even the best materials can fail. Assess the specific needs of your project. A well-planned maintenance schedule can save money and prevent costly disruptions.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5