In the world of plumbing, the choice of piping material is pivotal for ensuring both safety and efficiency in installations. Schedule 80 pipe, known for its thicker walls and higher pressure tolerance compared to Schedule 40, is a preferred option for many professional plumbers. Renowned industry expert, John Thompson, once said, “Using Schedule 80 pipe for high-pressure applications can significantly reduce the risk of leaks and failures.” His insight underscores the importance of making informed decisions when it comes to plumbing projects that demand durability and reliability.

Effective scheduling of Schedule 80 pipe in your plumbing projects can enhance operational workflow and overall project success. This involves not only understanding the specifications of the pipe but also mastering its application in various plumbing scenarios. By strategically planning the installation process and accounting for factors such as pipe length, fittings, and system pressures, plumbers can optimize their workflow and minimize downtime.

As we delve into the intricacies of scheduling Schedule 80 pipe, this guide will provide essential tips and best practices for maximizing efficiency in your plumbing projects. With the right approach, you can ensure that your installations meet the highest standards of safety and performance, making the most of this robust piping option.

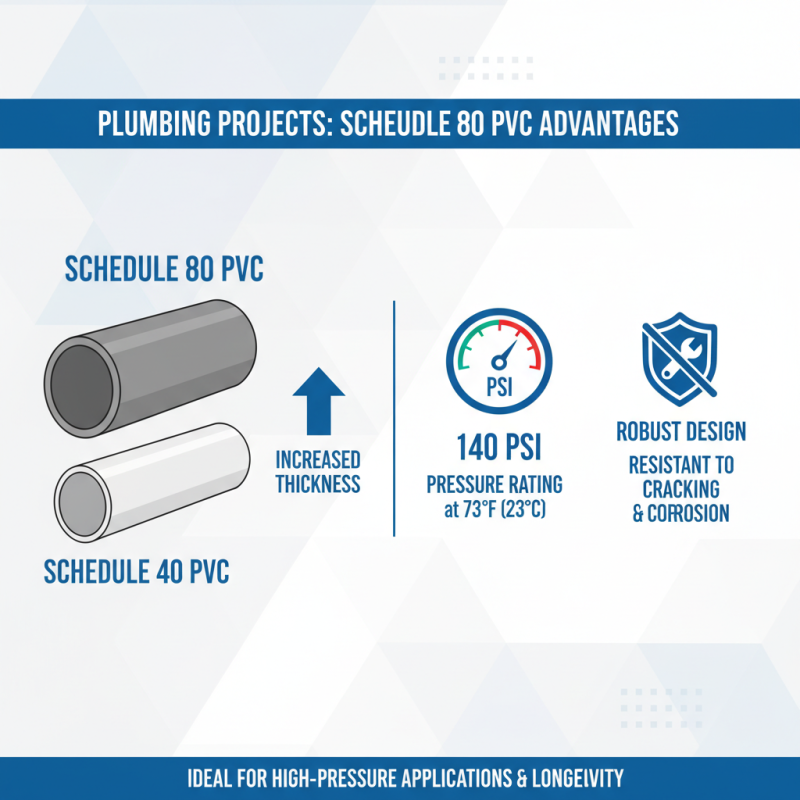

When working on plumbing projects, understanding the characteristics of 80 pipe, commonly referred to as schedule 80 PVC, is crucial. This type of pipe is known for its increased thickness compared to schedule 40, which translates to higher pressure ratings. According to industry standards, schedule 80 PVC can handle pressures of up to 140 PSI at 73°F, making it suitable for a variety of applications where elevated pressures are a concern. Its robust design also makes it resistant to cracking and corrosion, which is essential for ensuring longevity in residential and commercial plumbing systems.

Moreover, the versatility of schedule 80 pipe enhances its appeal in plumbing applications. It can be used for chemical processing, water distribution, and HVAC installations, as it can withstand harsh environmental conditions without degrading. The material is lightweight, making transportation and installation easier, yet it maintains a significant strength-to-weight ratio. Industry data indicates that the use of schedule 80 pipe in plumbing has grown by approximately 15% year-over-year, showcasing its increasing preference among plumbing professionals who prioritize durability and reliability in their projects. Understanding these characteristics ensures that plumbers can effectively schedule and select the right materials for their specific needs.

Assessing project requirements is crucial when scheduling 80 pipe for plumbing projects. The first step involves understanding the specific needs of the project, which includes the type of plumbing system, the scale of the installation, and the compliance with local codes. A report from the American Society of Plumbing Engineers (ASPE) indicates that nearly 60% of plumbing issues stem from improper planning and scheduling. Consequently, a detailed assessment can prevent delays and additional costs later in the project lifecycle.

When evaluating the project requirements, it’s also essential to consider factors such as the flow rate and pressure demands. According to the National Plumbing Code, choosing the right size of pipe can significantly impact system performance and efficiency. For example, 80 pipe is commonly used for both cold water supply and drainage applications; however, it is critical to analyze the specific flow demands and potential friction losses in the system. By leveraging software tools and modeling techniques, plumbing professionals can predict the necessary pipe sizes and configurations, ultimately streamlining the scheduling process and ensuring optimal performance of the plumbing system throughout its lifespan.

Creating an effective plumbing project schedule is essential for ensuring timely completion and efficient resource allocation. Start by gathering all necessary project details, including the scope of work, materials needed, and labor requirements. This initial step helps you visualize the overall timeline. Once you have a clear understanding of the project requirements, break down the tasks into smaller, manageable phases. Each phase should include a realistic time estimate based on the complexity and materials involved, particularly for large components like 80 pipe installations.

Next, prioritize your tasks to reflect their dependencies and critical path. Schedule the procurement of materials ahead of time to avoid delays, and allocate time for potential contingencies. It’s important to remain flexible and be prepared for adjustments as the project progresses. Regularly review the schedule and communicate with all team members to ensure everyone is aligned with timelines and responsibilities. Effective scheduling not only enhances efficiency but also minimizes risks associated with project overruns and miscommunication. By following these structured steps, you can streamline your plumbing project and achieve successful outcomes.

Effectively managing inventory and resources for 80 pipe in plumbing projects requires a systematic approach that prioritizes efficiency and cost-effectiveness. According to a report by the Plumbing Manufacturers International (PMI), the average plumbing contractor can reduce project costs by up to 20% through better inventory management practices. This includes adopting just-in-time (JIT) inventory systems, which not only minimize excess stock but also ensure that materials are available when needed without incurring unnecessary holding costs.

Additionally, implementing digital inventory tracking systems can significantly enhance resource management. A study from the National Association of Home Builders (NAHB) indicates that companies utilizing advanced inventory management software experience a 30% decrease in project delays due to materials shortages. For 80 pipe, this translates to maintaining optimal stock levels based on project forecasts, seasonal demand, and lead times for deliveries. Regular audits and reviews of inventory will further support accurate forecasting and help prevent overstock or stockouts, ensuring that plumbing projects run smoothly and on budget.

| Pipe Size | Quantity in Inventory | Recommended Order Level | Lead Time (Days) | Supplier |

|---|---|---|---|---|

| 1/2 inch | 150 | 50 | 5 | Supplier A |

| 3/4 inch | 120 | 40 | 7 | Supplier B |

| 1 inch | 100 | 30 | 10 | Supplier C |

| 1 1/4 inch | 80 | 25 | 12 | Supplier D |

| 1 1/2 inch | 60 | 20 | 15 | Supplier E |

Scheduling 80 pipe for plumbing projects often presents several common challenges that require careful consideration and strategic planning. One prominent issue is the variability in lead times for materials. Such fluctuations can disrupt project timelines, leaving contractors scrambling to adapt. To mitigate this, it’s crucial to establish strong relationships with suppliers and maintain a clear communication line. Regular updates on inventory levels can help anticipate shortages and facilitate timely orders, ensuring that projects remain on track.

Another challenge lies in accurately estimating the amount of 80 pipe required for a project. Incorrect estimations can lead to excess inventory, tying up capital and storage space, or insufficient materials, causing delays. To overcome this hurdle, employing detailed project planning and using precise measurement techniques is essential. Utilizing project management software can aid in tracking material requirements, allowing for adjustments as the project progresses. By integrating a robust scheduling system that includes buffer time for unexpected issues, plumbing professionals can streamline their operations and enhance efficiency.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5