Choosing the right PVC tube for your projects can be more complex than it appears. According to the Plastics Industry Association, the PVC market in North America is projected to grow at a steady rate of 3.2% annually. This growth brings both opportunities and challenges. Industry experts like Dr. Emily Wright, a materials scientist, emphasize the importance of informed choices. She once noted, "Understanding the properties of PVC tubes is crucial for project success."

When selecting a PVC tube, project requirements must guide your decision. Not all PVC tubes are created equal, and varying factors can influence their performance. For instance, thickness and flexibility are essential for durability and functionality. In some cases, clients overlook these specific requirements, resulting in subpar outcomes. Such mistakes can lead to increased costs and project delays.

In addition to basic specifications, consider environmental factors. Some PVC tubes may not resist extreme conditions effectively. A detailed understanding is necessary. If your project demands high performance, stress-testing data becomes vital. Decisions based solely on price often lead to regrets. Ultimately, a thoughtful approach will lead to better results and greater satisfaction in your projects involving PVC tubes.

When choosing a PVC tube, it's crucial to understand the various types available. PVC tubes come in different grades and thicknesses. Some are designed for low-pressure applications, while others can handle high-pressure systems. Rigid PVC tubes, for example, provide strength, making them ideal for structural uses. Flexible PVC tubes are more practical for plumbing and drainage projects.

The clarity of the material may also vary. Transparent PVC tubes allow for visibility, which is beneficial in certain applications. This can help monitor fluid flow or inspect for blockages. However, not all transparent tubes hold up well under UV exposure. It's essential to consider the environment in which the tube will be used.

Lastly, modifications can be a factor to consider. Some tubes are easier to cut and join than others. Ensure that the connectors match the type of tube chosen. Many people overlook these details, leading to project setbacks. Each type of PVC tube has its unique benefits and drawbacks; understanding them will help you make an informed choice.

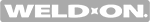

Choosing the right PVC tube for your project involves several key factors. One critical aspect is the dimension and size of the tube. You should consider the inner diameter and wall thickness. These dimensions affect the durability and flexibility of the tube. For instance, a thicker wall can handle higher pressure, but it might be less flexible.

When selecting sizes, think about your project's specific needs. If you need a lightweight solution, a smaller diameter may suffice. However, a larger diameter can accommodate higher flow rates. Pay attention to compatibility with existing components. A common mistake is assuming all sizes will fit. Measure your fittings carefully.

Do not forget about the environment. UV exposure can degrade PVC over time. Consider using protective coatings. It may add to costs, but it extends the tube's lifespan. Take the time to reflect on your choices. Each project demands different needs, and sometimes the best option isn’t the most obvious one. Analyze your requirements closely to avoid future issues.

When assessing the quality of PVC tubes, several key factors come into play. First, consider the material's thickness and density. Research from the Plastics Industry Association indicates that thicker walls usually enhance durability and resistance. A minimum thickness of 2mm is often recommended for standard applications.

Next, examine the certifications of the PVC tube. Compliance with ASTM standards is vital. A study by the American Society for Testing and Materials found that certified tubes significantly reduced failure rates in pressure applications. Look for specifics like the UV resistance rating, particularly if the tubes will be exposed to sunlight.

Finally, inspect the surface finish. A smooth surface often indicates better manufacturing processes. Rough surfaces may trap dirt and harbor bacteria in food-related projects. An informed choice here can make the difference between a reliable project and one prone to issues. Remember, not all PVC tubes meet the same quality standards. It’s crucial to do your research and ensure you pick reliable materials that fit your specific needs.

When selecting a PVC tube for your project, understanding your specific application is crucial. Different projects demand different types of tubes. For instance, consider the required flexibility and strength. Some applications need rigid tubes, while others can work with more flexible options. Take time to assess these needs.

Tip: Measure the diameter accurately. A tube that’s too big or small can lead to issues. Ensure it perfectly fits your components. This simple step can save you from headaches later.

Another aspect to consider is the environment where the tube will be used. Will it be exposed to UV light? Moisture? Use UV-resistant options, if necessary. Reflect on the conditions your tube will face. This could affect its longevity.

Tip: Understand the pressure requirements. Some applications need high-pressure tolerance. Others demand low-pressure performance. Knowing this can guide your choice. Don’t overlook these details; they can significantly impact your project's success.

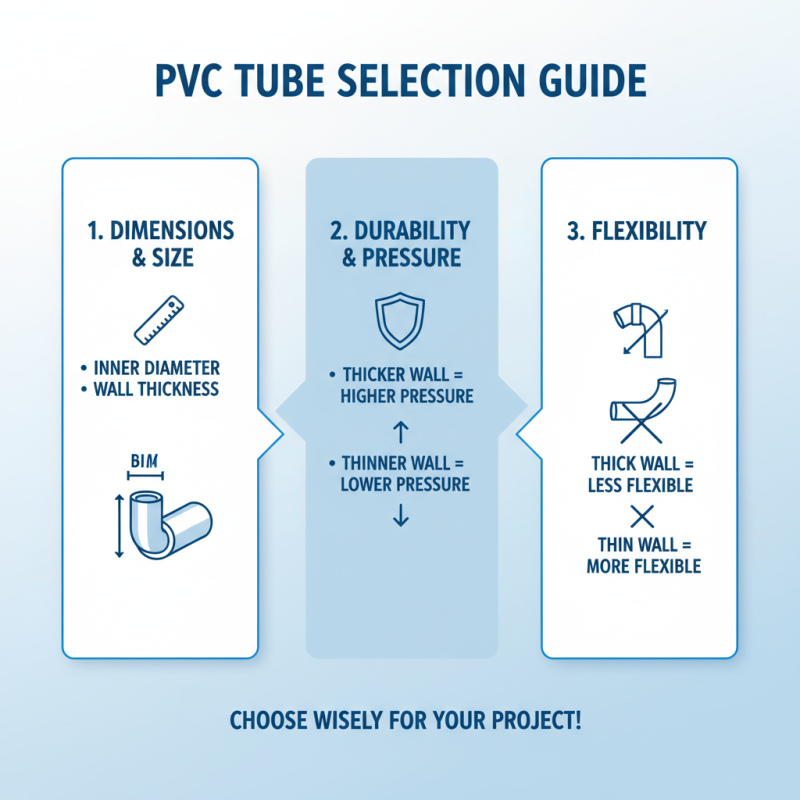

Choosing the right PVC tube can be tricky. Many overlook important factors. A common mistake is ignoring the tube's diameter. Ensure it fits your project’s requirements. Too narrow, and it won’t work. Too wide, and it may look odd.

Another frequent error is neglecting the tube’s schedule rating. This indicates its thickness and pressure capacity. Using a tube with a wrong rating could lead to failures. Always check the specifications. Some projects demand durable options, while others may need flexibility. Think carefully about the usage context.

Lastly, many choose based solely on price. This can lead to poor quality or unsatisfactory performance. It’s vital to balance cost with functionality. Read reviews or seek advice from experienced users. Reflect on your choices to avoid repeated issues. Making informed decisions saves time and resources in the long run.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5