In the world of plumbing and construction, understanding the intricacies of Schedule 80 PVC fittings is vital. Renowned expert, John Baker, once stated, "Schedule 80 PVC fittings are essential for systems requiring higher pressure ratings.” This statement captures the essence of why these fittings are so important. Schedule 80 PVC fittings are thicker and more durable than their Schedule 40 counterparts, making them suitable for demanding applications.

These fittings are widely used in industrial settings and chemical processing. Their resistance to corrosion gives them an edge over metals. However, adopting Schedule 80 PVC fittings can pose challenges. For instance, their rigidity may complicate installation in tight spaces. Proper cutting and fitting techniques are crucial to achieving a reliable connection. Neglecting this can lead to leaks or failures, which can be costly.

In addition to installations, workers must regularly inspect these fittings. Over time, even robust materials can degrade. Taking these steps ensures reliability and safety. The demand for Schedule 80 PVC fittings continues to grow, but knowledge and care in their application can't be overlooked. It’s a balancing act of understanding their strengths and potential pitfalls.

Schedule 80 PVC fittings are crucial in various plumbing and industrial applications. They are designed for high-pressure systems, providing durability and strength. These fittings have thicker walls compared to Schedule 40 PVC, which helps withstand higher temperatures and pressures. Common specifications include a nominal pipe size ranging from ½ inch to 24 inches. This makes them versatile for many projects.

When choosing Schedule 80 PVC fittings, consider the application. They are ideal for chemical handling, water supply, and irrigation systems. Make sure to check the pressure ratings before use. This can help prevent leaks and costly repairs later. Always verify compatibility with other materials in the system.

Tip: When cutting PVC, use a saw designed for plastic. This minimizes the risk of cracking.

Tip: Check for proper alignment when installing fittings. Misalignment can cause leaks over time.

Keep in mind that while Schedule 80 fittings are strong, they can still be brittle. Care is needed during installation to prevent damage. Always wear safety gear when working with PVC materials.

Schedule 80 PVC fittings are popular in various industries. These fittings are thicker and stronger than standard PVC fittings. They can withstand higher pressure and temperature. This makes them ideal for critical applications.

In the chemical processing industry, Schedule 80 PVC fittings are essential. They can handle corrosive substances safely. A study by the Plastics Industry Association shows a rise in demand for chemical-resistant materials. Construction sites also frequently utilize these fittings. They are often used in irrigation systems and drainage. A report estimates that the global PVC fittings market will reach $16 billion by 2025.

Tips: When selecting Schedule 80 PVC fittings, consider the specific pressure requirements of your system. Ensure proper installation to maximize performance. Sometimes, the initial cost may seem high. However, the long-term durability can offset that expense.

Healthcare facilities also use Schedule 80 PVC fittings. They help transport water and gases safely. In a recent survey, over 70% of healthcare workers noted the fittings' reliability. It’s important to ensure that these fittings are regularly inspected. This practice helps maintain their integrity over time. Poor maintenance can lead to failures, which are costly.

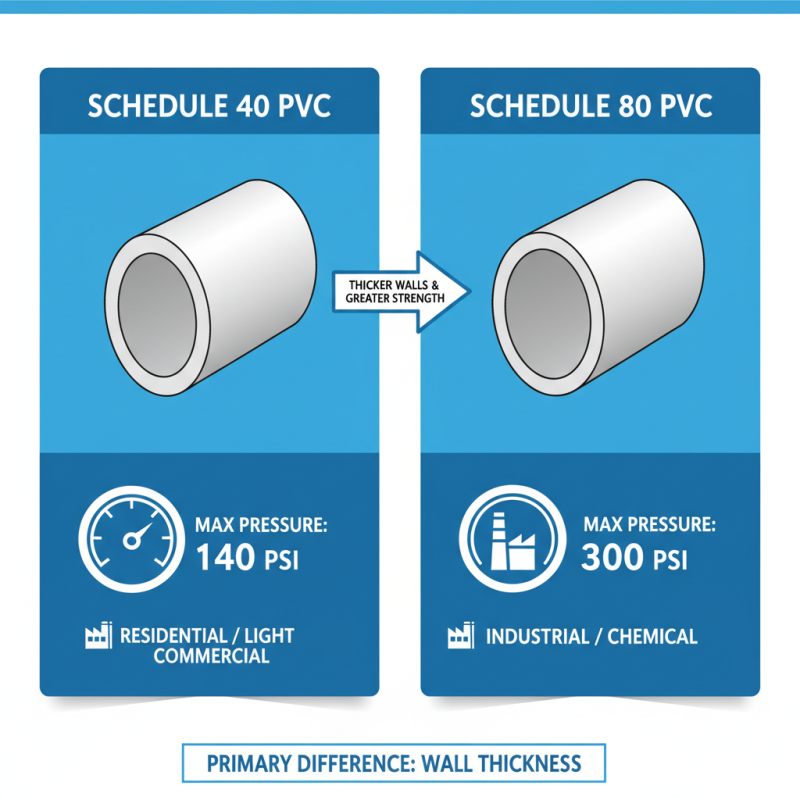

When comparing Schedule 80 and Schedule 40 PVC fittings, the primary difference lies in their wall thickness. Schedule 80 fittings have thicker walls than Schedule 40. This makes them stronger and more suitable for high-pressure applications. According to industry reports, Schedule 80 can withstand pressures up to 300 PSI, whereas Schedule 40 typically handles about 140 PSI. This capability makes Schedule 80 ideal for industrial uses and chemical handling.

However, thicker walls also mean heavier fittings. This could pose challenges during installation. The added weight makes handling difficult, particularly for large-scale projects. Additionally, Schedule 80 fittings are generally more expensive than Schedule 40. While some might argue the added durability is worth the cost, others could find the price limitative.

Another aspect to consider is the compatibility of fittings. Schedule 80 and Schedule 40 use the same pipe diameter measurements, but their applications differ significantly. Some professionals mistakenly mix the two, especially in less demanding environments. This oversight can lead to leaks or failure under pressure, highlighting the importance of careful selection. Understanding the specific needs of each project is crucial to avoid costly mistakes.

When it comes to installing Schedule 80 PVC fittings, preparation is key. Ensure all surfaces are clean and dry before starting. Use a fine brush or cloth to eliminate dust. Measure twice, cut once – precision in cutting pipes prevents errors during assembly. A good fit minimizes leaks and reduces the need for repairs later.

Next, applying the appropriate solvent cement is crucial. Make sure to apply it evenly around both the fitting and the pipe. Overapplying can result in drips, leading to unsightly finishes and weaker joints. After fitting, hold the joint in place for 30 seconds. It allows the cement to bond properly.

It’s also important to consider the environment where the fittings are installed. Extreme temperatures and high-pressure scenarios can stress joints. Regularly check for signs of wear or damage. Don't overlook signs of fading or cracks. It’s better to address these issues early. Emphasizing quality installation today can prevent significant challenges later.

| Dimension | Size (inches) | Pressure Rating (psi) | Common Uses | Installation Guidelines |

|---|---|---|---|---|

| 1/2" Tee | 0.84 | 280 | Water Distribution | Use primer and solvent cement |

| 3/4" Elbow | 1.05 | 200 | Irrigation Systems | Ensure proper alignment during installation |

| 1" Coupling | 1.32 | 200 | Drainage Systems | Use a level to ensure horizontal connections |

| 2" Cap | 2.5 | 280 | Ventilation | Ensure a snug fit to avoid leaks |

| 4" Reducer | 4.5 | 150 | Chemical Handling | Follow manufacturer’s cement instructions |

Schedule 80 PVC fittings are popular in various

industrial applications due to their strength and durability. When it comes to maintenance, these fittings

require attention to ensure longevity. A study from the Plastics Pipe Institute indicates that properly maintained Schedule 80 PVC systems can last for over

50 years. However, neglect can lead to

premature failures.

Inspecting fittings regularly is crucial. Look for signs of UV

degradation or chemical exposure. Even minor surface cracks can escalate if not addressed. Using a soft

brush or cloth can help remove debris without causing scratches. According to industry reports,

cleanliness directly affects the fittings' lifespan.

Occasional replacements might be inevitable, especially in high-stress environments. Plan for these changes

to avoid unexpected downtime. A report from the American Society for Testing and Materials emphasizes

proper installation as a key factor for longevity.

Misalignments can create stress points, leading to leaks. Ignoring this may result in costly repairs later.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5