When embarking on a project that requires hdpe pipe fittings, careful consideration is essential. These fittings play a critical role in the overall performance of piping systems. It is vital to understand the various options available. Choosing the right type can save both time and money in the long run.

HDPE pipe fittings are known for their durability and resistance to chemical corrosion. However, not all fittings are created equal. Different projects may require distinct specifications. The size, pressure rating, and compatibility with existing systems should be evaluated. Understand what you need before making a decision.

Reflecting on the importance of quality, some may overlook the details in fittings. A poor choice can lead to leaks or failures. It’s essential to research and compare products thoroughly. This ensures that the hdpe pipe fittings selected will meet the project demands successfully. Being attentive to these aspects can truly impact project outcomes.

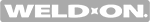

When working with HDPE pipe fittings, understanding the basics is crucial. HDPE, or high-density polyethylene, is known for its durability and resistance to corrosion. It is commonly used in various applications like water supply, gas distribution, and drainage systems.

Pay attention to the fitting types. There are several options, including elbows, tees, and reducers. Each fitting serves a specific purpose, so choose wisely based on your project needs. Ensure that your fittings match the pipe’s diameter for a snug fit. A good fit can prevent leaks.

Consider the installation process as well. Some fittings require specific tools for assembly. Not all DIYers have these tools readily available. Evaluate your capabilities before making a decision. Always have backup fittings on hand. It’s not uncommon to mismeasure or miscut pieces. An extra fitting can save you time and frustration.

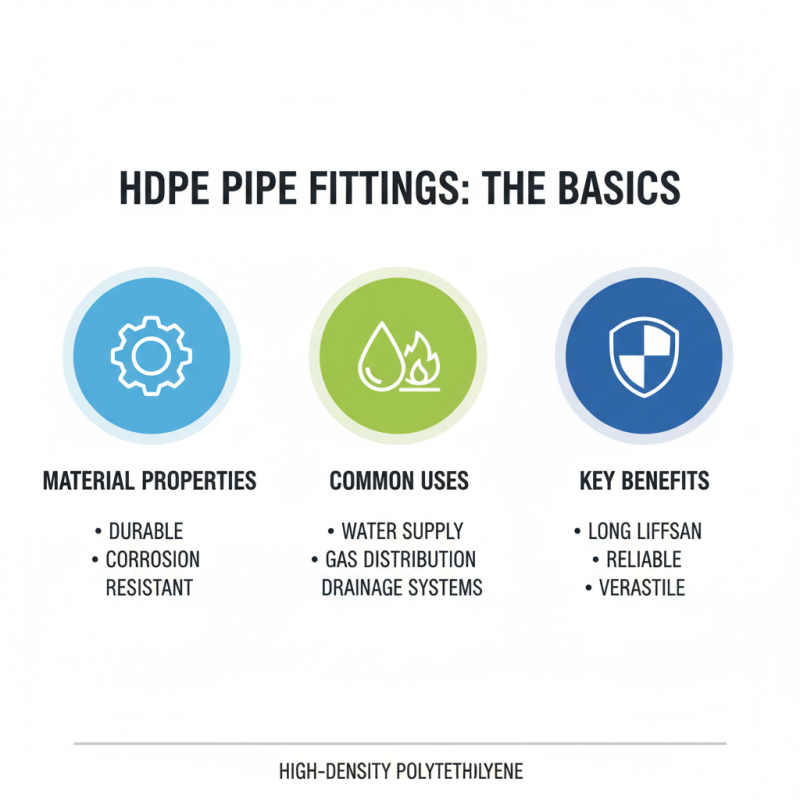

Lastly, think about the environment where the pipes will be located. Extreme temperatures and chemicals can affect HDPE performance over time. Ensure the chosen fittings can withstand these conditions. Planning for potential issues can make a significant difference in the longevity of your project.

When selecting HDPE pipe fittings, several key factors come into play. Consider the application of your project. Different settings require different fittings. For instance, industrial applications may demand stronger, more durable materials. The environment also matters; exposure to extreme temperatures may affect fitting choices.

Additionally, the fitting size is crucial. Measure the pipe diameter accurately to ensure compatibility. A misfit can lead to significant issues later. Always factor in pressure ratings. High-pressure applications need fittings that can withstand stress.

Lastly, review the installation process. Some fittings require special tools, which can affect project time and budget. Reflect on your team’s expertise as well. It's important to ensure everyone is comfortable with the installation requirements. Choosing the right fittings means balancing quality and convenience. A misstep here can lead to costly repairs down the line.

When selecting HDPE pipe fittings, it's essential to understand the various types and their specific applications. There are several key categories of fittings, including elbows, tees, and couplings. Each type serves a distinct purpose.

Elbows allow for changes in direction, critical in complex piping systems. Tees help create branch connections, providing flexibility. Couplings join two pipe sections securely, ensuring a smooth flow.

In addition to type, consider the fitting size. Mismatched sizes can lead to issues. A wrong fit may result in leaks or reduced flow efficiency. It's important to measure pipe diameters accurately. Another factor is the pressure rating of fittings. High-pressure applications require durable materials. Look for fittings that match your project’s requirements.

Installation practices also matter. Even with the best fittings, improper installation can cause problems. Taking the time to plan and execute the installation correctly is crucial. Regular inspections and maintenance of the fittings can prevent unforeseen issues. Proper care extends the lifespan and functionality of the system.

When selecting HDPE pipe fittings, evaluating quality and certification standards is crucial. The quality of materials affects longevity and performance. According to industry reports, fittings made from high-density polyethylene (HDPE) can last over 50 years when properly installed. However, not all fittings are created equal. It's essential to verify that your selected fittings meet relevant standards.

Look for certifications from recognized organizations, like ASTM or ISO. These certifications indicate that the fittings have undergone rigorous testing. For example, the ASTM D3261 standard outlines requirements for butt fusion fittings. Adherence to such standards ensures better resistance to pressure and stress. Nonetheless, many products on the market may lack proper certification.

Always inspect the fittings for visible defects. A small crack can lead to costly leaks in the long run. Surprisingly, around 30% of HDPE fittings tested in various studies were found to have some level of manufacturing defects. These shortcomings highlight the need for diligence. Ensuring the quality of HDPE fittings is not just about compliance; it's about safeguarding your entire project.

When working with HDPE pipe fittings, proper installation is crucial for long-lasting performance. Start by ensuring that all pipe ends are cut straight. Uneven cuts can lead to misalignments. Use a pipe cutter for cleaner edges. This step greatly reduces the risk of leaks in your system.

Next, cleanliness is key. Remove any dirt or debris from both the pipe and fitting surfaces. Even small particles can create weak points. Consider using a cloth to wipe down the fitting. Also, when joining fittings, apply the appropriate lubricant. This helps in achieving a tight seal. It's easy to overlook this detail, yet it can significantly impact the integrity of the connection.

Pay attention to the jointing techniques. Some installers rush this process, which may lead to future failures. Ensure that you follow the recommended heating times if you're using fusion methods. Overheating can compromise the material, while insufficient heating may not create a strong bond. After installation, inspect each joint. A thorough check can reveal issues before they escalate. Regular maintenance checks can save you time and resources in the long run.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5