Plastic pipe fittings play a crucial role in plumbing and construction. These versatile components are essential for efficient water management and fluid transport. Renowned industry expert, Dr. Emily Carter, states, "Plastic pipe fittings are a game-changer in modern plumbing." Her insights highlight the growing significance of these fittings in today’s construction landscape.

In residential and commercial projects, plastic pipe fittings simplify installations. They are lightweight, easy to handle, and reduce the overall project time. With their resistance to corrosion and ability to withstand high pressures, they address many long-standing plumbing challenges. However, not all plastic fittings are created equal.

Selecting the right type requires in-depth knowledge and experience. Sometimes, contractors overlook specific requirements, leading to leaks or failure. Proper education and awareness can prevent costly mistakes. Learning to use plastic pipe fittings effectively is essential in achieving lasting results in plumbing and construction projects.

Plastic pipe fittings are essential in residential plumbing applications. They are lightweight and durable, making them an excellent choice for various installations. According to a recent market report, the plastic pipe fittings market is projected to reach $20 billion by 2026, driven by the growing demand for efficient plumbing solutions.

Many homeowners are opting for plastic fittings over traditional materials like metal. This is due to their resistance to corrosion and ease of installation. For instance, PVC and CPVC pipes are popular for water supply lines. These materials can handle high temperatures and pressures. However, a common concern is their long-term durability when exposed to UV light. Some contractors recommend using protective coatings or installing them indoors to mitigate this.

Plastic pipe fittings are also versatile. They can be used in various systems, from drainage to irrigation. A study highlighted that about 70% of plumbers prefer plastic over metal in non-pressurized applications. Yet, it's important to select the right type of fitting for each application. Not every plastic fitting is suitable for every job. Proper planning and knowledge are essential to avoid potential issues during installation.

Plastic pipe fittings have gained popularity in plumbing and construction due to several key advantages over metal alternatives. A report by the Plastic Pipe and Fittings Association states that plastic fittings are significantly lighter than metal. This weight advantage can reduce transportation costs. In addition, plastic is resistant to corrosion, which is a common issue with metal pipes. A study indicates that corrosion-related failures contribute to 20% of plumbing-related complaints.

Moreover, plastic fittings often have lower installation costs. They are easier to handle and require less labor. Installation of plastic fittings can save up to 30% in labor costs according to industry data. Furthermore, they can withstand higher pressures than many metal options. This capability makes them suitable for various applications. However, some professionals question the long-term durability of plastic compared to metal. While plastic is resilient, its performance can vary with temperature changes.

Ultimately, choosing between plastic and metal can be complex. The initial savings with plastic don’t always account for its life span or potential repair needs. Industry insights suggest that the decision should factor in the specific application context and local environmental conditions.

Plastic pipe fittings are essential in modern plumbing and construction. They are lightweight, durable, and resistant to corrosion. Their application can significantly reduce construction costs. When comparing traditional materials, plastic fittings are often more affordable. They require less manpower to install due to their lightweight nature. This leads to time savings on projects.

In addition to cost savings, plastic fittings help minimize waste in construction. Their flexibility allows for easier adjustments during installation. However, some may overlook the long-term impact of using plastic materials. Over time, the environmental cost may become a concern. This can lead to a need for more sustainable choices in the future.

Regardless, the immediate financial benefits are hard to ignore. Many builders appreciate that plastic fittings can streamline their projects. Still, it's essential to balance short-term gains with long-term implications. The construction industry must consider these factors as it evolves.

| Use Case | Description | Cost Efficiency Impact | Durability |

|---|---|---|---|

| Water Supply Systems | Used for transporting potable water. | Reduces installation costs due to lightweight nature. | High resistance to corrosion. |

| Drainage Systems | Facilitates the effective management of wastewater. | Cost-effective for large-scale plumbing projects. | Resistant to chemicals and harsh conditions. |

| Irrigation Systems | Used in agricultural settings to deliver water. | Lower installation and maintenance costs. | Long-lasting under various weather conditions. |

| HVAC Systems | Used for venting and duct systems. | Contributes to energy efficiency and lower heating/cooling costs. | Good thermal insulation properties. |

| Electrical Conduits | Protects electrical wiring from environmental factors. | Lowers costs related to material and labor. | Non-conductive and resistant to moisture. |

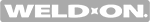

The trend towards sustainability is reshaping the plastic pipe fittings industry. According to the Plastics Industry Association, around 9% of plastic waste is recycled. This is a stark contrast to the overall recycling rates for other materials. The construction and plumbing sectors can do better. The future hinges on improving recycling processes and promoting circular economy practices.

Recycled plastic pipe fittings offer a lower carbon footprint. They require less energy to produce than virgin materials. Some studies estimate that using recycled plastics can cut greenhouse gas emissions by as much as 70%. However, there are challenges. Not all plastic materials are easily recyclable. Compatibility issues arise in different applications. Additionally, public awareness is vital. Many customers still prefer new materials over recycled options.

As technology progresses, innovative recycling methods are emerging. Advanced sorting and processing techniques can enhance the quality of recycled plastic. Research indicates that consumers are increasingly willing to pay more for sustainable products. Yet, supply chain management remains a concern. Effective distribution of recycled materials is not as polished as it could be. There is much room for improvement in industry practices.

The use of plastic pipe fittings in plumbing and construction is expansive. However, industry standards and regulations play a crucial role in their application. These guidelines ensure safety and efficiency. The American Society for Testing and Materials (ASTM) sets benchmarks for material quality and performance. Compliance with these standards is essential for durability and safety in installations.

In many regions, local codes stipulate specific requirements for plastic fittings. Checking compliance can be overwhelming but is vital. Inspectors often focus on joint integrity and resistance to pressure. Regular training for contractors on these standards can help avoid costly mistakes.

Tips: Always verify the certification of fittings before purchase. Look for markings that indicate compliance with recognized standards. Enhancing knowledge about local regulations can save time and resources. Remember, not all plastic fittings are created equal. Mistakes can lead to failures and repairs, which nobody wants.

This chart illustrates the various applications of plastic pipe fittings in plumbing and construction, highlighting their predominant usage areas. The data showcases the percentage distribution of different applications based on industry standards and regulations.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5