In today's competitive market, effective packaging is crucial. Clear PVC, a versatile material, is gaining popularity among businesses. According to Lisa Adams, a packaging expert, "Clear PVC allows brands to showcase their products while ensuring protection." This explains its rise in various industries.

Clear PVC offers transparency, durability, and flexibility. Consumers can see products clearly, which enhances their buying experience. However, clear PVC is not without challenges. For instance, managing costs can be difficult for some businesses. The balance between quality and affordability requires careful consideration.

Being innovative with clear PVC can lead to new solutions. Some companies struggle with creativity in their packaging designs. This is a missed opportunity. By exploring diverse applications of clear PVC, brands can improve their visual appeal. It is essential to reflect on how well you are using clear PVC in your packaging strategy.

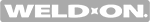

Clear PVC (Polyvinyl Chloride) is increasingly recognized for its role in effective packaging solutions. It offers several key properties that enhance packaging performance. For instance, clear PVC is lightweight yet durable. This combination leads to reduced shipping costs. According to a report by Smithers Pira, the global market for rigid plastic packaging is expected to reach $300 billion by 2024, highlighting the demand for materials like clear PVC.

The transparency of clear PVC allows consumers to see the product. This is vital in retail environments. Eye-catching displays can increase sales. Additionally, clear PVC is resistant to moisture and chemicals, providing protective barriers. A study published in the journal Packaging Technology and Science notes that clear PVC performs well in maintaining product integrity over time, making it suitable for a variety of products.

Despite its benefits, clear PVC does come with some environmental considerations. The production process can generate emissions. Efforts to recycle PVC are ongoing but face challenges. As consumer awareness grows, brands must balance packaging efficiency with sustainability. There’s room for improvement in how clear PVC is perceived and utilized in eco-friendly initiatives. This reflects a need for ongoing innovation in the packaging industry.

Selecting the right type of clear PVC for packaging is crucial. Different thicknesses and formulations exist. According to industry reports, clear PVC packaging can reduce costs by up to 30% compared to other materials. However, not all PVC is created equal. Certain formulations may lack the necessary durability for heavy items, leading to potential product damage during transport.

Consider the specific requirements of your products. For lightweight items, thinner grades may suffice. Yet, for heavier products, thicker PVC is necessary to prevent failures. Be mindful of clarity as well. Some options can appear cloudy, affecting shelf appeal. A study indicated that 70% of consumers prefer clear packaging, as it showcases the product inside.

Explore the options carefully. PVC can also be recycled, but users must check local guidelines. Some PVC types may not be permitted in specific regions. Always conduct tests to determine performance. Manufacturing inconsistencies can arise, leading to unexpected failures. Think about these aspects when making your selection.

Clear PVC packaging has become popular in many industries. It offers durability and transparency. When designing effective clear PVC packages, attention to detail is crucial. One technique involves creating precise dimensions. Ensure the package fits the product snugly. Loose packaging can lead to damage during shipping.

Incorporating unique designs can make the packaging stand out. Use creative features like cut-outs or custom shapes. These elements grab consumer attention. However, balance is key; too much complexity can detract from functionality. Also, consider sustainable practices. Are there eco-friendly materials that work with clear PVC? Exploring alternatives can lead to better solutions.

Test different designs with various products. Learn from failures and successes. Feedback from users can provide valuable insights. Strive for continuous improvement. Effective packaging not only protects but also communicates brand values clearly.

This chart illustrates the effectiveness of various clear PVC packaging techniques based on factors such as visibility, durability, and cost-efficiency.

Clear PVC is gaining traction in packaging due to its versatility and clarity. It provides excellent visibility for products, enhancing customer engagement. However, sealing these packages effectively is crucial to maintain the integrity of the contents. According to a 2022 industry report, improper sealing can lead to product spoilage, costing businesses up to $500,000 annually.

When sealing Clear PVC, consider using heat sealing methods. This technique helps create an airtight seal. An airtight package keeps moisture and contaminants out. Yet, heat sealing requires precise temperature control. Too high a temperature can damage the PVC. Too low might not seal effectively. Experimentation is often necessary.

Additionally, clear PVC responds well to adhesive applications. However, choosing the right adhesive is essential. Some adhesives may break down the PVC over time. A study showed that up to 30% of adhesive failures occur due to poor material compatibility. This indicates a need for thorough testing before large-scale production. Balancing aesthetics, functionality, and reliability remains a challenge for many manufacturers.

Clear PVC has gained popularity in the packaging industry due to its transparency and durability. However, using it raises important sustainability considerations. Traditional PVC production involves harmful chemicals and significant energy consumption. This poses challenges for eco-conscious companies. They must weigh the benefits against the environmental impact of PVC manufacturing.

When evaluating clear PVC, one must consider its recyclability. While PVC can be recycled, the infrastructure for recycling it is not universally available. Many facilities do not accept PVC due to contamination risks. This ambiguity leads to an ongoing debate within the industry. Can clear PVC packaging contribute to a circular economy? Or does it primarily serve short-term convenience?

Moreover, consumers are increasingly demanding sustainable packaging options. They prefer materials that minimize waste and have a lower carbon footprint. Brands must adapt to these preferences, even if it means reassessing their materials. Those who rely on clear PVC packaging should explore alternative solutions that prioritize environmental health. Finding the right balance is essential for long-term success in this ever-evolving market.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5