When considering plumbing solutions, HDPE fittings stand out as a reliable choice. According to a report by Smith & Associates, the market for HDPE fittings grew by 12% last year. This growth reflects their durability and resistance to corrosion. Industry expert Dr. Jane Thompson states, "HDPE fittings are not just a trend; they represent the future of sustainable plumbing."

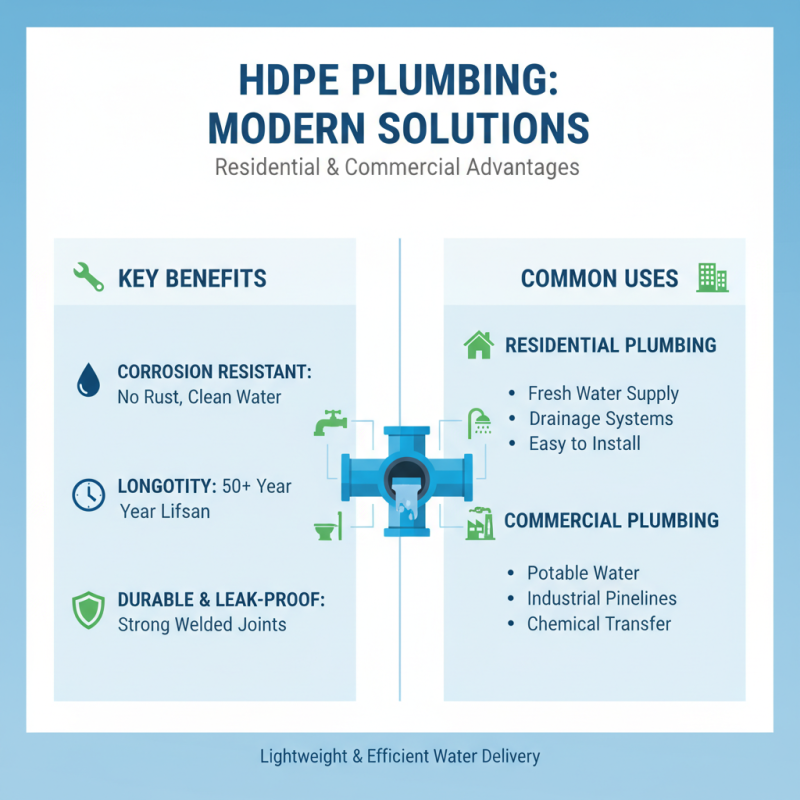

These fittings provide longevity in a demanding environment. Unlike traditional materials, HDPE withstands extreme temperatures and pressures. This makes them ideal for both residential and commercial applications. People often overlook long-term cost benefits, focusing only on immediate expenses. In the long run, choosing HDPE fittings can significantly reduce maintenance costs.

However, it's important to acknowledge that not all HDPE fittings are created equal. Quality can vary among manufacturers. In some cases, lower-cost options may lead to issues, such as leaks or failures. Careful selection is crucial to ensure performance and reliability. As the plumbing industry evolves, HDPE fittings are likely to lead the way, aligning with sustainable practices and performance standards.

HDPE, or high-density polyethylene, is becoming a popular choice in plumbing systems. Its unique properties make it suitable for various applications. HDPE is lightweight, strong, and resistant to corrosion. This means it won’t break down easily, even in harsh conditions. It can handle temperature fluctuations without becoming brittle.

If you're considering HDPE fittings, think about your specific plumbing needs. Tip: Inspect your current system for any signs of wear. If you find leaks or damage, HDPE may be a strong alternative. The installation process is relatively straightforward. However, ensure proper techniques are used. Poor installation could lead to issues down the road.

Another benefit of HDPE is its flexibility. This allows it to be laid out in unconventional spaces. Remember, not every project suits HDPE. Tip: Consult with experts if unsure. They can provide insights tailored to your unique requirements. Choosing the right materials is crucial. It can save you both time and money, but the decisions can get tricky. Think carefully.

HDPE fittings are gaining popularity in plumbing for good reasons. Compared to traditional materials like PVC, metal, and galvanized steel, HDPE provides unique advantages. It is flexible, lightweight, and resistant to corrosion. These features can save you time and money in repairs. Traditional materials often fail when exposed to harsh conditions. They can rust or crack over time, leading to leaks and costly repairs.

Using HDPE fittings can minimize these risks. They can withstand extreme temperatures and pressures. Additionally, they do not leach harmful chemicals into drinking water. For your plumbing projects, this is a significant advantage. It ensures safer, cleaner water for you and your family.

**Tip:** Always check local regulations regarding plumbing materials. Not all areas allow HDPE for every application. It's essential to confirm these details. Also, consider the environmental impact. HDPE is recyclable, making it a more sustainable choice. Yet, improper disposal can negate this advantage. Balance your choices carefully for a better future.

HDPE fittings are increasingly popular in both residential and commercial plumbing. They offer numerous advantages, including corrosion resistance and longevity. Homes often benefit from HDPE pipes in water supply systems. These pipes are lightweight and easy to install. They can bring fresh water quickly and efficiently.

In commercial settings, HDPE is essential for various applications. Restaurants and hotels use HDPE fittings for drainage and waste management. The material can handle high temperatures and pressures. This makes it suitable for heavy-duty use. However, installation can be tricky. Inexperienced plumbers may struggle with proper sealing, leading to leaks.

Overall, while HDPE fittings are beneficial, attention to detail is crucial. A small installation mistake can lead to future problems. Ensuring proper techniques can save headaches later. Homeowners and business owners should consider professional guidance. This can prevent costly repairs and inefficient systems in the long run.

When installing HDPE fittings, preparation is key. Start by gathering your materials. You’ll need HDPE pipes, fittings, a fusion machine, and safety gear. Make sure your workspace is clean. This reduces errors during the installation process. Measure pipes carefully to ensure accurate cuts. A simple mistake can lead to leaks later.

Next, align the pipes and fittings. The fusion machine requires specific temperatures for bonding. Check the manufacturer's guidelines for this. It can take time to get it right. If you rush, you might end up with weak joints. Aim for consistency in your technique. After fusing, let the joint cool naturally. Patience is essential.

As you finish, inspect each joint thoroughly. Look for any signs of uneven fusion or cracks. If any issues arise, it’s crucial to address them immediately. Ignoring small problems can lead to bigger issues down the road. Document your process. This will help in future projects. Each step, no matter how small, matters greatly.

| Feature | Description | Benefits |

|---|---|---|

| Durability | HDPE fittings are resistant to corrosion and are highly durable. | Long lifespan and reduced replacement costs. |

| Flexibility | HDPE pipe can bend without breaking, allowing for easier installation. | Less fittings required, reducing installation time. |

| Chemical Resistance | Resistant to a wide range of chemicals, making it suitable for various applications. | Improved safety and versatility in plumbing systems. |

| Ease of Installation | Can be installed using heat fusion or electrofusion methods. | Reduces labor costs and installation time. |

| Cost-Effectiveness | Lower material and maintenance costs compared to traditional materials. | Saves money over the life of the system. |

| Step | Description |

|---|---|

| 1 | Prepare the site and gather all necessary materials. |

| 2 | Cut the HDPE pipes to the required length using a suitable cutter. |

| 3 | Clean the pipe ends and fittings to ensure a secure joint. |

| 4 | Use a heat source or electrofusion process to join the fittings. |

| 5 | Allow the joints to cool and ensure they are secure before pressure testing. |

When it comes to plumbing, durability is a key factor. HDPE fittings stand out due to their resistance to corrosion. Unlike metal pipes, they don’t rust over time. This ensures longevity, even in harsh environments. Imagine a pipeline that withstands chemicals and extreme temperatures. Such resilience goes a long way in reducing maintenance costs. Fewer repairs mean more savings down the road.

Cost-effectiveness is another advantage of HDPE fittings. Though the initial investment may seem high, consider the long-term savings. They last significantly longer than traditional materials. This longevity translates into fewer replacements, lowering overall expenses. Moreover, installation is often quicker, reducing labor costs. Sometimes, we overlook the hidden costs in plumbing projects. It’s crucial to weigh these factors carefully when making a decision. Investing in HDPE means fewer headaches later on.

Sign up for our mailing list to stay informed and up to date with our latest news and products!

(905) 832 – 0600

2175-A Teston Road

Maple, Ontario

L6A 1T3

(780) 451 – 0238

24790 – 117 Avenue

Acheson, Alberta

T7X 6C2

(604) 882 – 1564

9511 – 194A Street

Surrey, British Columbia

V4N 4G4

(306) 955 – 6005

3926 Arthur Rose Avenue Saskatoon, Saskatchewan

S7P 0C9

(450) 687 – 2721

2750 Rue Bernard-Lefebvre

Laval, Quebec

H7C 0A5